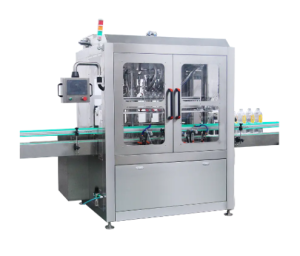

BUY A HOT SAUCE BOTTLE FILLER A hot sauce bottle filler will help you increase your bottling production, operational efficiency, and profitability. With the growth of the hot sauce market, demand for dairy and sauce processors grows as well in the form of cost-effective and scalable production solutions. This blog provides a bird's eye view at what benefits will stem from incorporating a top-line bottle filler at your production line

Parameter Adjustment to Maximize Throughput

Hot sauce bottle fillers are designed to streamline the bottling process, so that producers can bolster production times as they get to market, without cutting corners when it comes to quality. Depending on the viscosity of the sauce and the volume of the bottle, modern fillers can operate at speed rates of 20 to 100 bottles per minute. This high throughput is essential for meeting market demand and executing large orders quickly.

Increase Accuracy & Lower Waste of Final Products

Bottling is all about precision. With advanced bottle fillers each bottle precisely gets the same amount of sauce, helping to prevent overfill and underfill situations. This precision reduces waste considerably — high-end fillers usually allow a deviation of just ± 0.5% of the complete fill volume. Waste reduction is not only cost effective but also contributes to sustainability practices an increasing concern amongst consumers.

Wide Scale of Business Processes

The acquisition of high-quality bottling machinery, e.g. a hot sauce bottle filler, is an investment that can streamline your operations as your business expands. Increasing production does not always mean that an increase in labor is also needed, if the right equipment is present. This scalability allows your production capacity to grow with your business cost-effectively and efficiently.

Maintain Product Consistency

Delivers a product with high consistencies in quality, helping reinforcement the brand and satisfy the customers authentic ShareConsistency of a high-quality product strengthens the brand and ensures customer satisfaction They help ensure each unit of product is the same as the next, key to keeping a brand reputation. Quality throughout all of your products is what keeps people coming back and establishing a good name in an industry is paramount.

Adapt to Market Changes Fast

Modern bottle fillers are more flexible than older designs, requiring only minor changes to accommodate different sized and shaped bottles. This modularity also means that you are able to adapt to new trends on the market or increase your variety of products with minor investments in new equipment.

Compliance with Health Standards Run in Proper Order

Food safety is not something that can be treated as optional in the hot sauce manufacturing business. Most are made of high-end stainless steel and some other food safe materials, and they offer simply cleaning. This will help you to adhere to the tight health and safety regulations with the least headaches, aggravation, and costly recalls and will keep your brand reputation bright.

Make no mistake, a topnotch bottle filler isn't just an operational upgrade, it's a choice with consequences that impact on every facet of your brewing business. Whether hot sauce makers are looking to speed up their production capabilities, improve their hot sauce quality standards or meet relevant regulations, the bottling equipment will play a crucial role in enabling them to effectively compete in the market.